System Components & Specifications

Detection:

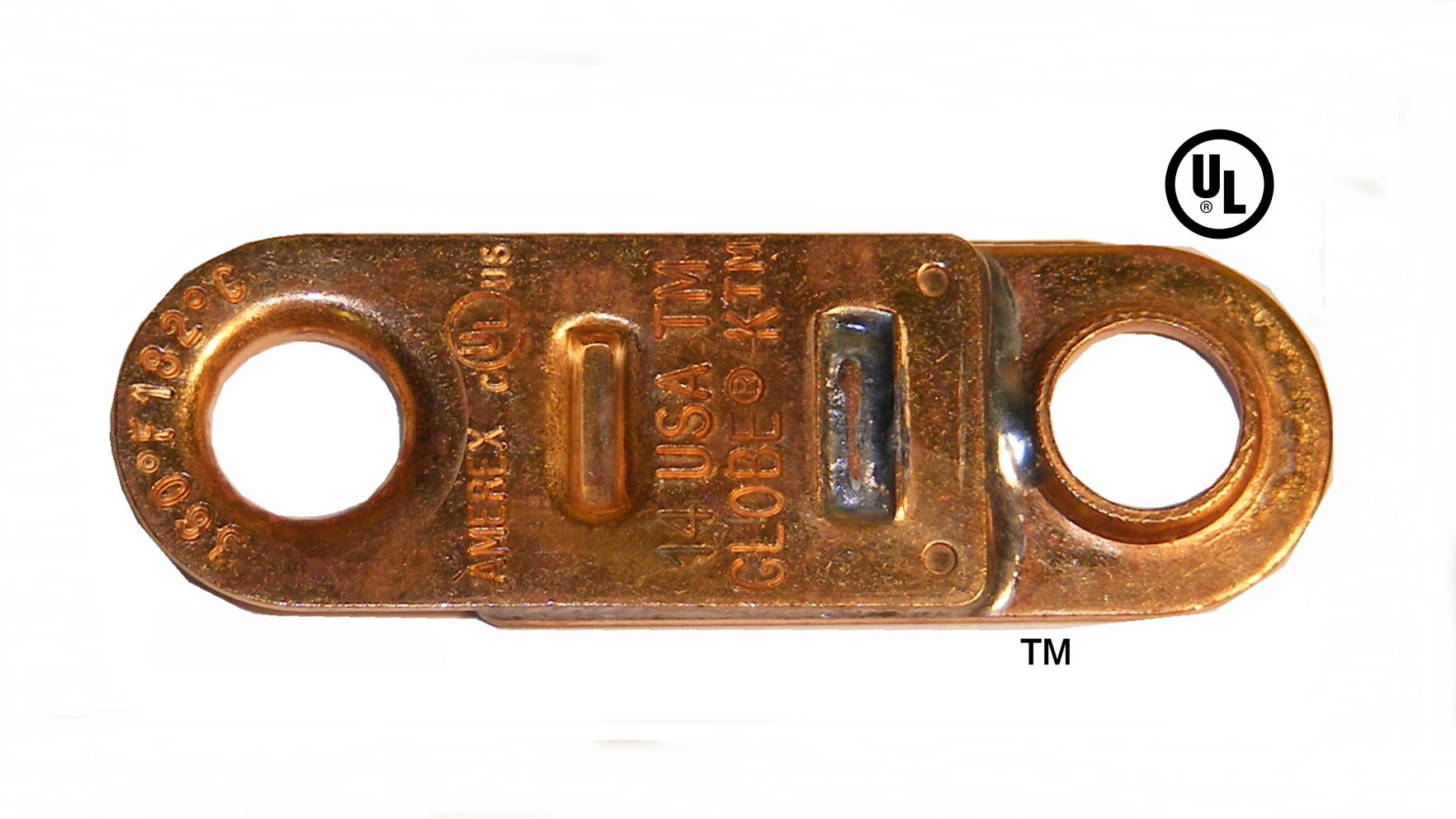

- The detection network in a mechanically actuated system uses a continuous cable run with detectors holding fusible links, specifically listed and rated for use with the Amerex KP system.

- The PRM uses a linear pneumatic detection system consisting of tubing and end of line fitting. The tubing is pressurized through a small accumulator inside the enclosure, and is specifically listed and rated.

Manual Release:

- The manual pull stations are a dual action type. Both a ring pin and a lever must be pulled in order to discharge the system.

Agent:

- The wet chemical agent is a potassium acetate based solution that suppresses grease fire through saponification and cooling. The agent has a pH of less than 9 and does not harm stainless steel surfaces.

Cylinder:

-

The agent cylinders are mild seel, tested to 480 PSI, they are available in capacities of 2.75, 3.75, 4.75, and 6 gallons, they are fully factory charged with Amerex KP liquid agent and pressurized to 240 PSI.

Nozzles and Suppression:

- The discharge nozzles are appliance specific and made of chrome plated brass. They consist of a body with tip, strainer, tip, retaining nut, and blow off cap.

General System Specifications:

- The KP system is pre-engineered and shall be designed, installed, and maintained according to NFPA 96 and NFPA 17A - Standard for Wet Chemical Extinguishing Systems.Amerex

- The MRM is spring loaded and has electrical, mechanical, or pneumatic outputs. It is capable of actuating one to ten agent cylinders using a nitrogen cartridge. It is operated either automatically by the detection network or manually using a remote manual pull station.

- The actuation cylinder or nitrogen cartridge is filled with 10 cu. in of nitrogen and has an integral pressure gauge which allows easy field verification of pressure.